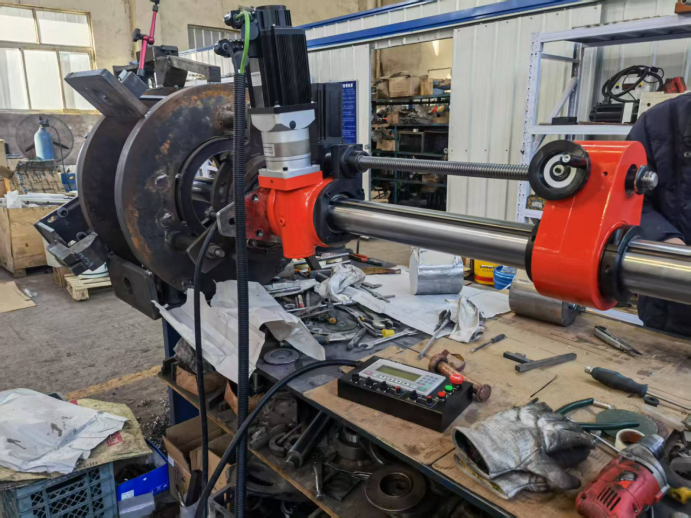

Model 60 Boring Machine

Mainly used for a variety of mechanical structure of the axle pin hole, slewing hole, articulated hole after the complementary welding processing, or for reaming after the set, multi-row and hole, a one-time positioning processing of multiple holes to ensure that the coaxiality of multiple holes;

Axial movement and cutting performance without vibration;

Feed and spindle infinitely adjustable speed;

Boring bar adopts the structure of alloy steel, machined, heat-treated with high-precision, high hardness, fatigue resistance, wear-resistant and other characteristics;

Motor The controller is equipped with dynamic time-delay braking device to avoid rotation when stopping;

The equipment has the extended function of boring end face, and customers can choose and match according to the processing needs.

Axial movement and cutting performance without vibration;

Feed and spindle infinitely adjustable speed;

Boring bar adopts the structure of alloy steel, machined, heat-treated with high-precision, high hardness, fatigue resistance, wear-resistant and other characteristics;

Motor The controller is equipped with dynamic time-delay braking device to avoid rotation when stopping;

The equipment has the extended function of boring end face, and customers can choose and match according to the processing needs.

Detailed Description

Product parameters

| Product name | Model 60 Boring Machine |

| Place of origin | China |

| Product specifications | TXT-60 |

| Purpose | Boring (Expandable to milling flat surfaces, patching internal holes, etc.) |

| Main motor power | 3KW |

| Voltage | 220V/380V 50/60HZ |

| Working stroke | 450mm (support customization) |

| Main machine speed | 0-90r/min (according to customer requirements) |

| Bore diameter | 70-500mm |

| Feed speed | Infinitely adjustable |

| Machining roughness | Ra3.2 |

| Roundness of machined hole | ≤0.02mm |

Operation site

Product Video