Single point greaser

Ensures that equipment is continuously filled with grease at regular intervals.

Provides continuous lubrication of lubrication points in hazardous environments without stopping the equipment.

Extension tubes and other accessories can be installed wherever lubrication is desired.

Transparent viewing window displays the amount of grease being continuously released.

Continuous pressure removes contaminants from the bearings.

Can be mounted in any direction up to 360° and can be used in mobile, underwater or freezing environments.

Minimizes the risk of bearing damage

Detailed Description

SP series electric single-point greaser

The SlMPLUBE SP series is a simple, reliable automatic lubricator for use in variable temperature or remote installation applications such as vibration, confined space or hazardous environments.

① The oil filling speed is not affected by temperature

② The maximum lubrication pressure during the entire dispensing period is 12 bar

③ Various lubrication intervals can be set

④ Transparent tank for real-time checking of remaining capacity

⑤Red-yellow-blue LED indicators show lubricator status

⑥ The external power supply can be linked with the equipment power start/stop

⑦ Suitable for direct and remote installation

Grease-containing or non-grease-containing can be selected. Depending on the application, we offer a wide range of high quality grease and lubricant dispensers, as well as grease-free dispensers that can be filled in-house for special applications.

Technical parameters

| Model | SP125/SP250 |

| Greaser capacity | 125ml/250ml(refillable) |

| Repeat oil replenishment times | Up to 10 times (seal life influence) |

| Applicable oils | Thin oil or grease not higher thanNLGI cl.2 |

| Operating temperature range | -20°C~ +60°C(with the use of suitable grease) |

| Maximum working pressure | Maximum 12 bar(175psi) |

| Longest lubrication line | 3m (10 feet) |

| Dimension |

125ml diameter 82mm*height 178mm 250ml diameter 82mm*height 225mm |

| Protection level | IP65 |

| Power supply type | 3V lithium battery pack /24V external power supply |

| Setting lubrication intervals | 15 days/1,3, 6, 9, 12 months |

| Battery Lifetime | 12 months maximum |

| Port | Thread R1/2 |

SE series motorized single-point greaser

1. Providing safe, precise and reliable lubrication to a single lubrication point.

2. Mechatronic drive design, accurate measurement, applicable to a wide range of ambient temperature.

3. It can be mounted directly on the lubrication point and operates immediately after a simple setup of the duty cycle.

4. Precise oil replenishment, the time interval can be set from 1 to 24 months.

5. This grease dispenser uses a standard nozzle that can be refilled with grease over and over again.

Grease-containing or non-grease-containing is available. Depending on the application, we offer a wide range of high-quality grease and lubricant fillers, as well as grease-free fillers for special applications.

Technical parameters

| Model | SE/FB150,SE/FB300 |

| Grease filler capacity | 150ml,300ml(refillable) |

| Repeat oil refill | Refillable grease |

| Applicable oils | Dilute oil or grease with a viscositynot higher than 2# |

| Temperature range | -20°C~ +60°C(please choose the appropriate grease) |

| Working pressure | Maximum 10 bar |

| Dimension |

150ml Diameter 70mm*Height 135mm 300ml Diameter 70mm*Height 200mm |

| Protection level | Ex ib llC T4 Gb |

| Power supply type | Disposable Li-ion battery pack or 24VDC external connection. |

| Oil replenishment cycle | 1-24 months |

| Battery Lifetime | Support to finish a can of grease |

| Port | Thread R1/4 |

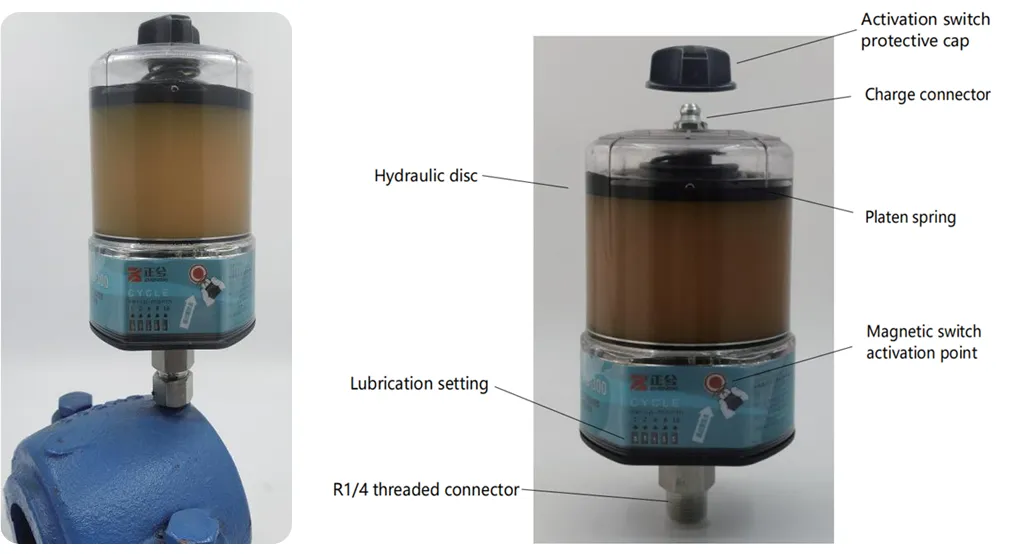

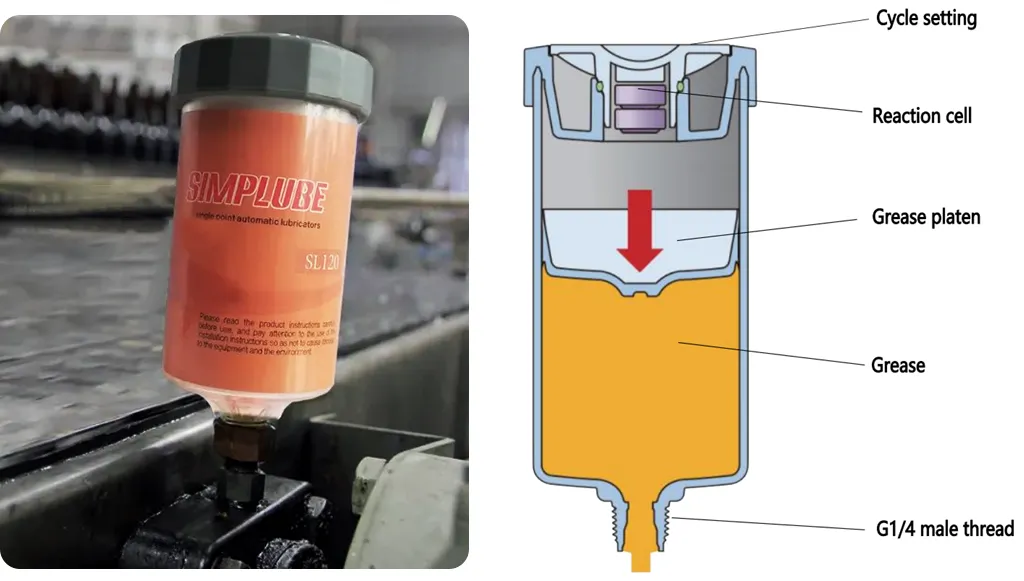

SL series pneumatic single-point greaser

Principle of operation

SlMPLUBE SL series automatic grease injectors do not containpumps, batteries, motors and other parts, no power or compressed air is required for use, once installed and activated, it will work automatically within your set cycle of use, each automatic grease injector contains its unique electrochemical actuator mechanism on the top of the injector, no springs or other mechanical parts, to adjust the time dial, the electrochemical reaction occurs after the contact of the chip. The energizer is activated and the resulting steady and increasing gas pressure pushes apiston that slowly squeezes out the grease. After the activationof the grease filler, the gas generated by the battery reaction is absolutely sealed in the top mechanism of the grease filler, which will not contaminate the grease in the grease filler, not to mention the surrounding environment. When the automatic grease dispenser is in operation, the transparent observation window clearly shows the amount of grease released.

Grease-containing or non-grease-containingcan be selected.

Depending on the application, we offer a wide range of high-quality grease and lubricant fillers, as well as grease-free fillers for special applications.

Technical parameters

| Model | SL120/SL60 |

| Grease capacity | 120ml/60ml |

| Repeat oil refill | Refillable grease |

| Applicable oils | Thin oil or grease nothigher than NLGl cl.2 |

| Temperature range | -20°C~ +60°C(please choose the appropriate grease) |

| Working pressure | Maximum 5.5 bar |

| Dimension | Diameter 50mm*Height 118mm |

| Protection level | IP65 |

| Drive type | Gas-driven |

| Setting lubrication intervals | 1,3, 6, 9, 12 months |

| Grease-free weight | 76g |

| Weight of oil and grease | 185g |

| Port | Thread G1/4 |