Wire rope lubrication maintenance cleaning system

Famous domestic wire rope manufacturers are located in Guizhou, Jiangsu Nantong, Wuxi, Hubei, Tianjin and Ningxia, etc. Imported wire ropes commonly found in the Chinese market come from the United States, the United Kingdom, Germany, Sweden, France, Australia, Japan, South Korea and so on.

Specification

There are three general classifications of wire rope specifications

Surface classification: galvanized steel wire rope, glossy steel wire rope, plastic coated steel wire rope.

Application classification: crane ropes, sling ropes, hoisting ropes, crane ropes, tower ropes, electric hoist ropes, elevator ropes, drilling rig piling ropes, rotary drilling rig ropes, gantry winch ropes, gondola ropes, basket ropes, construction machinery ropes, ropeways ropes.

Structural classification: point contact wire rope, line contact wire rope, surface contact wire rope, multi-layer strand non-rotating wire rope, triangular strand wire rope, multi-layer strand surface contact wire rope, sealed wire rope.

Detailed Description

Current status of wire rope maintenance

Four major limitations

● Lack of lubrication maintenance.

● Outdated lubrication method.

● No cleaning of wire ropes.

● Poor performance of grease.

Manual maintenance

Most of the domestic wire rope cleaning and lubrication is a regular manual application, with a brush or other tools dipped in grease (oil) and then applied to the wire rope. This maintenance method has many problems.

● Poor lubrication effect, waste of grease and environmental pollution.

The use of brushes and other coating tools, there are uneven coating, oil film is too thick, the pressure is small, resulting in small lubricant adhesion and poor internal penetration and other shortcomings, grease (oil) is difficult to enter the wire rope inside, and the phenomenon of waste is particularly serious.

● Dangerous operation mode, endangering personal safety.

In the cleaning, the wire rope running speed is faster, while the wire rope in the running process has a flexible, not easy to control, may jeopardize the personal safety of workers. In particular, working at height has a greater operational risk.

● Low working efficiency, high labor intensity, unable to clean.

Lubrication is operated with tools such as brushes and rags or steam cleaned with detergents, which is time-consuming and ineffective.

Equipment Maintenance

A few companies use ordinary lubricators for lubrication. For example, they use surface grease spraying, grease injectors, and oiling machines. Such equipment lacks the cleaning function, and there is no pressure lubrication, the effect is not good, can not carry out in-depth maintenance of wire rope.

Wire Rope Lubrication System Composition

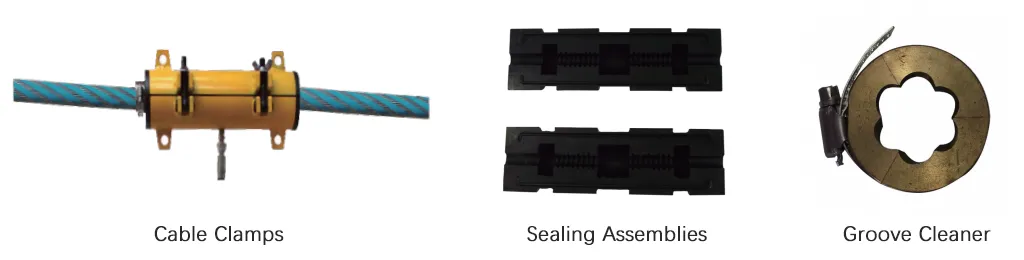

The wire rope lubrication and cleaning system consists of the following four main parts: high-pressure pumping system, cable clamping device, sealing components, groove cleaner and special grease for wire rope.

Note: Due to the different model specifications, the product illustrations vary

Introduction to wire rope lubricator parameters and selection

■ Large systems (diameters greater than 2''/51MM or larger) 6, 7, or 8 strand wire ropes, a large system configuration is recommended. The optimum air supply should be at least 30 to 40 CFM. most factory or shipboard air sources are sufficient to run a large system pump package.

■ Standard systems (less than 1.7/8” 148mm diameter) can operate with 15 CFM or larger compressors. Much depends on the speed at which the wire rope is run (during maintenance).

Selection Methods: Lubrication Systems, Consumables, Accessories