HENG ZHI / NEWS & BLOG

Unlocking Efficiency: The Advantages of Mini OD Flange Facing Machines

2025-05-27

The Ultimate Guide to Using a Portable Flange Facing Machine Table of Contents 1. Introduction to Portable Flange Facing Machines 2. Understanding the Importance of Flange Facing 2.1 The Role of Flange Facing in Manufacturing 2.2 Common Applications of Flange Facing Machines 3. Key Features of Portable Flange Facing Machines 3.1 Portability and Versatility 3.2 Precision and Accuracy 3.3 Durability

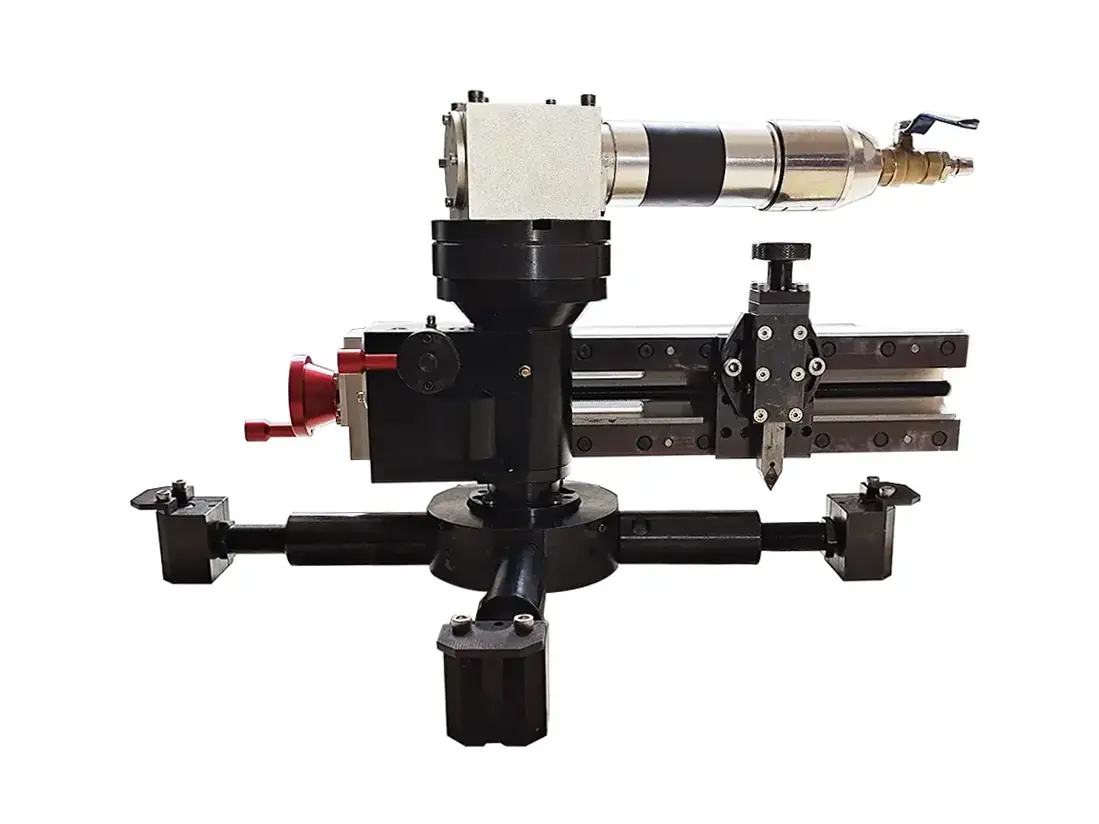

In the realm of manufacturing and machining, the ability to maintain high levels of precision and efficiency is critical. The Mini OD Flange Facing Machine stands out as a valuable tool designed to meet these demands, particularly in applications where space and portability are vital.

Mini OD Flange Facing Machines are engineered to perform precise operations on the outer diameter of flanges, ensuring that surfaces are machined to exact specifications. These machines are typically compact and portable, making them ideal for both shop and field applications. Their design often incorporates advanced features such as adjustable speed settings, easy-to-use controls, and robust construction to withstand various working conditions.

One of the primary benefits of using a Mini OD Flange Facing Machine is the significant time savings it offers. The machine's efficient operation allows for quick setup and execution of flange facing tasks, which is especially beneficial in environments where deadlines are tight. Additionally, by ensuring consistent surface finishes, these machines help reduce the need for rework and improve overall productivity.

Moreover, the Mini OD Flange Facing Machine is versatile and can be utilized for various materials, including steel, aluminum, and other alloys. This capability makes it an essential addition to any machining facility that frequently handles different types of flanges. The machine's adaptability ensures that manufacturers can maintain high-quality standards across diverse projects.

Precision is another critical aspect where these machines excel. The ability to achieve tight tolerances ensures that flanges fit perfectly in their respective applications, which is crucial for maintaining system integrity and performance. Whether in pipeline construction, pressure vessel manufacturing, or other industrial applications, the accuracy provided by Mini OD Flange Facing Machines can significantly impact the quality of the final product.

User-friendliness is also a vital consideration when evaluating any machining equipment. Many Mini OD Flange Facing Machines are designed with intuitive controls and simplified operational procedures, allowing operators to quickly become proficient, thus minimizing training time and increasing operational efficiency.

Additionally, maintenance of Mini OD Flange Facing Machines is typically straightforward, as many models are constructed with durability in mind. Regular maintenance helps extend the lifespan of the machine, ensuring that it remains a valuable asset in a manufacturing environment.

In conclusion, the Mini OD Flange Facing Machine represents a fusion of innovation and practicality in the manufacturing sector. By providing speed, precision, versatility, and ease of use, these machines are indispensable tools for professionals dedicated to enhancing their machining capabilities and achieving high-quality results. Embracing this technology can lead to notable improvements in operational efficiency and product quality.